desktop lathe

(spring 2022)

WHAT IS IT?:

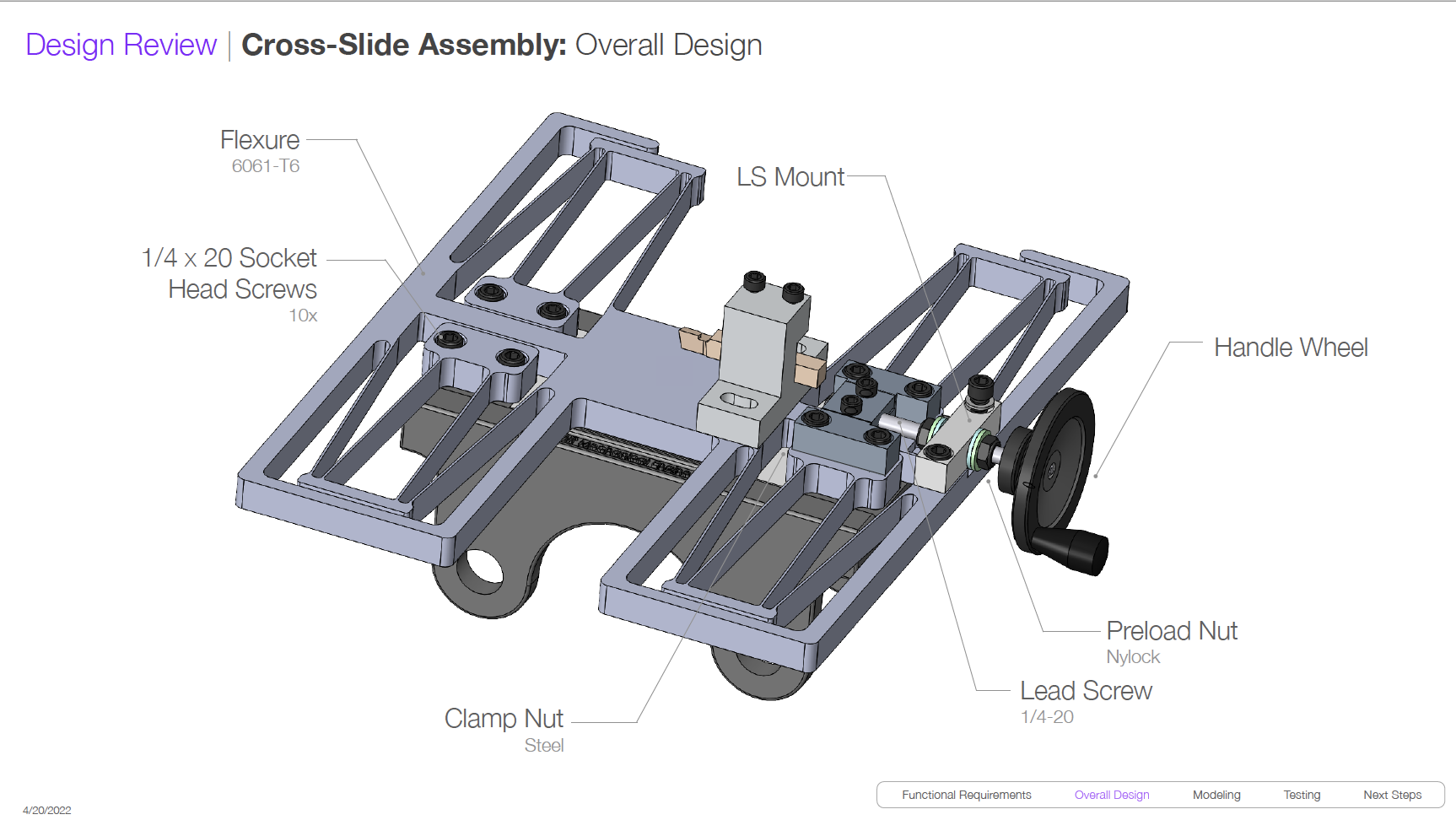

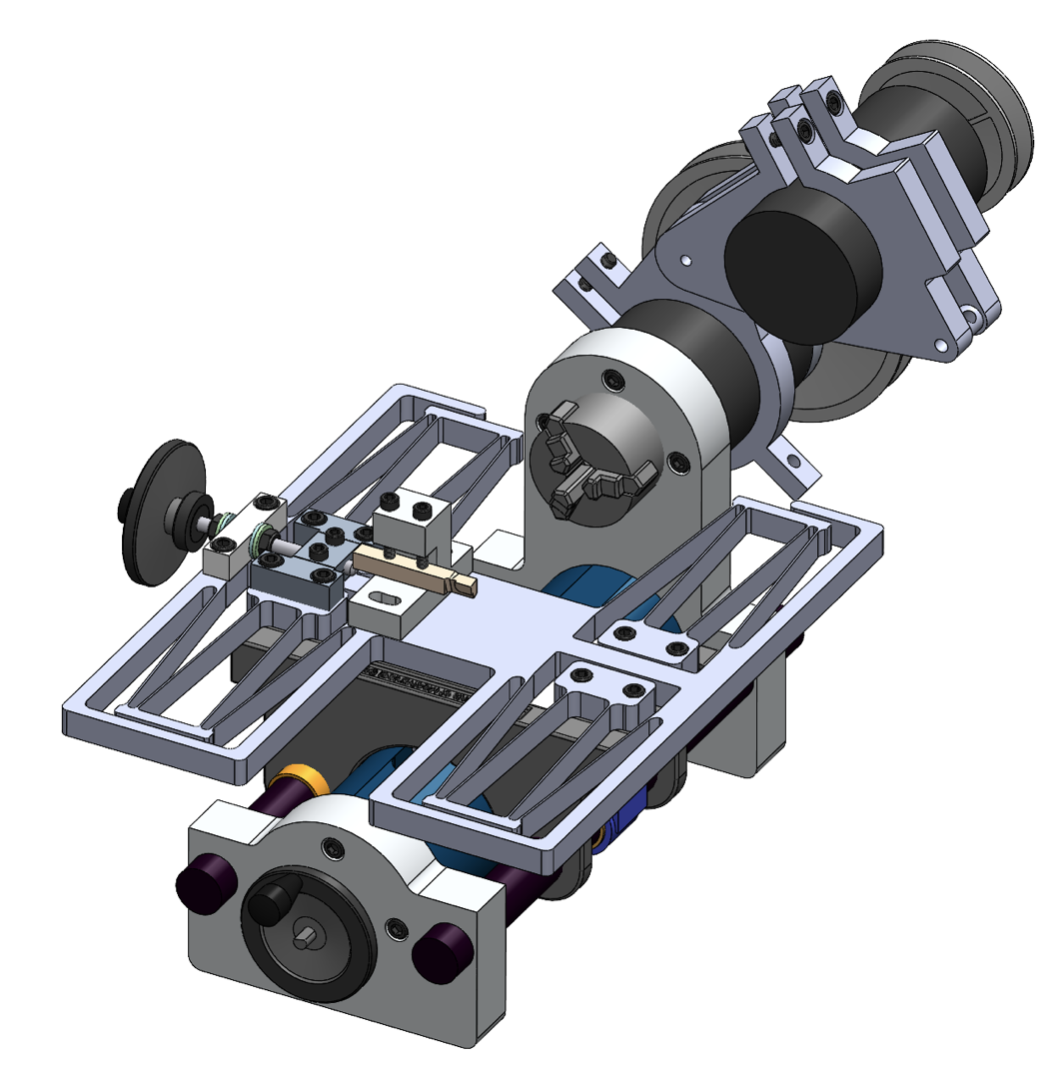

As part of MIT’s 2.72 Mechanical Design Principles course in Spring 2022, my team of 7 was task to design and fabricate a fully functional desktop lathe.

My team designed and manufactured a lathe capable of cutting aluminum stock (to 500N) to 25 microns of resolution, passing a drop test (from desk height) and could withstand the weight of a 55kg person standing on it.

ROLE:

I led a team of 7 students through the design process by managing meetings, Gantt timelines, deliverables, and product requirements. I assigned tasks and relevant DRI’s, and consistently monitored the project to meet each milestone (each component finished) on time. The process timeline went from functional requirement, modeling calculations, CAD, manufacturing, then testing to the requirements.

Managing the team and integrated aspects of the product meant I was responsible for defining and updating the functional requirements of the system level project as well as for each sub component. On the engineering side, this included many first order calculations to justify each numeric requirement, such as how many newtons of cutting force do we need to withstand.

As an engineer on the team, I did the stiffness and beam bending modeling for the spindle assembly to meet our 25 micron repeatability requirement. In addition, I conducted the analysis of the HTM’s (homogenous transfer matrix) for the whole assembly, as an exercise is tolerance analysis to understand how the tip of the cutting tool would deflect. This then led to proper selection the spacing of the bearings, dimension of the spindle shaft, and other parts, and material selection.

I manufactured many parts of the lathe as well. This included waterjetting the end caps for the spindle housing and parts of the cross slide flexure and the dancing man flexure. I milled the z-axis housing, and the clamp nut for the lead screw. I helped finishing of the parts and the assembly of the whole lathe.

Finally, I developed and integrated the Keynotes for all design reviews, making sure to convey relevant information like the design process, and whether or not the final product hit all functional requirements.

SKILLS:

design and manufacturing

3D modeling (Solidworks)

machining and fabrication

design documentation

project management