deep ocean underwater glider (DOUG)

(fall 2020)

WHAT IS IT?:

Current methods of ocean exploration and research lack the versatility and speed needed to collect data efficiently and effectively. The Engineering Systems Design Team (2.013) designed a system to tackle the challenges of creating a maneuverable and adaptable Autonomous Underwater Vehicle (AUV) to fill the present gap in technology. Our solution had to be capable of diving to depths of 1000 meters, completing 30-day long mission, and be easy and cheap to manufacture.

This project was done in a team of 25. My sub-team designed the structural hull of the system.

ROLE:

I worked as a member of the structural sub-team, as well as a member of the logistics task force.

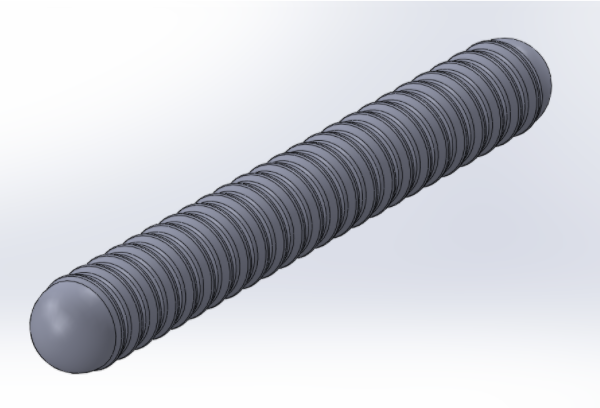

As part of the structural sub-team, I performed first hand calculations for our system, modeled as a thin wall pressure vessel. In addition, I conducted research for system verification methods for material selection of the hull. This included corrosion tests and hydrostatic pressure testing. We just moved into the design phase. I’ve assisted in design and calculations for a corrugated hull design and ribbed hull design, which is vastly novel compared to the smooth cylinder of current AUVs.

The reason we narrowed down our design selection to a corrugated hull and ribbed hull was to reduce the weight budget as much as possible, as opposed to the commercially straight aluminum tube.

I was also responsible for the fin mount system. I have designed it to be modular, in which the fins are bolted to the mount, and the mounts are attached to the hull via hose clamps. This system is quite each to manufacture and assemble and allows for easy replacement of the fins if necessary. It is capable of withstanding drag effects as well as an impact force of half the weight of the overall system.

As part of the logistics task force, my role is to perform cost optimization of manufacturing the whole system, as well as developing a more cost effective and efficient solution for AUV deployment. Logistics research also includes outreach to companies, professionals, and AUV experts.

SKILLS:

design and manufacturing

2D and 3D modeling (Fusion360, Solidworks)

mechanical analysis

design documentation

cost analysis

design progress cad, updated 11.30.2020

preliminary corrugated hull design

ribbed hull design